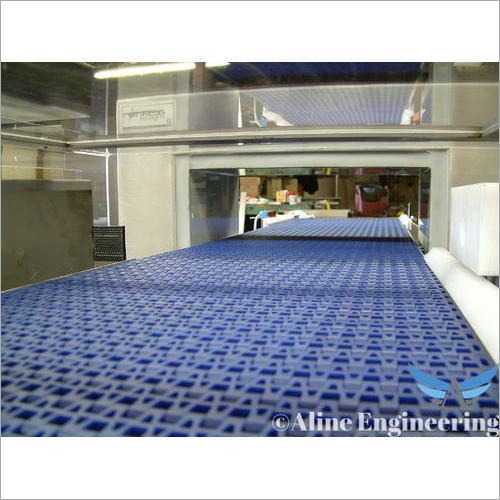

Plastic Belt Conveyor

Product Details:

- Belt Type Modular Plastic Belt

- Features Lightweight, Durable, Easy to Clean

- Thickness Belt: 5 mm

- Power Source Electric

- Surface Finish Powder Coated

- Material Plastic Belt, Mild Steel Frame

- Type Plastic Belt Conveyor

- Click to View more

Plastic Belt Conveyor Price And Quantity

- 12900 INR/Meter

- 1 Meter

Plastic Belt Conveyor Product Specifications

- No

- 220-240 V

- 0.75 kW

- Mild Steel Frame

- No

- Modular Plastic Belt

- Plastic Belt, Mild Steel Frame

- Variable, up to 30 m/min

- Belt: 5 mm

- Plastic Belt Conveyor

- Material Handling, Packing Lines, Assembly Conveyance

- Lightweight, Durable, Easy to Clean

- Up to 100 kg/meter

- Yes

- Corrosion Resistant

- Electric

- No

- Powder Coated

Plastic Belt Conveyor Trade Information

- 1000 Meter Per Month

- 3-5 Days

Product Description

Manual energy is being saved in transporting bulkier objects in the production areas and related fields with the usage of conveyor solutions. This Plastic Belt Conveyor comes forward as an industrial system that is put in use for transporting materials. Our offered conveyor system is worth installing because it fits into the expectations of the industries in terms of performance. The utilization of a plastic belt is done for placing items. This excellent quality plastic-based belt makes movement along the slotted track in the perfect manner for making the process of transporting goods utmost easier. Our Plastic Belt Conveyor is a popular choice among the modern industrial fields

Product details

| Capacity | 50-100 kg per feet |

| Voltage | 220 V |

| Brand | Aline |

| Belt Material | Rubber |

| Type | Plastic Belt Conveyor |

| Operating Speed | 1-2 m/s |

Versatile Design for Multiple Applications

Engineered for adaptability, this conveyor suits various industries, including material handling, packing lines, and assembly operations. With customizable belt width and adjustable length, it meets diverse operational requirements, making it a practical solution for most factory floors.

Reliable Performance and Efficiency

Powered by a gear motor, the conveyor ensures steady, low-noise movement at variable speeds up to 30 m/min. Its electric operation (220-240 V, 0.75 kW) provides consistent performance, while the modular plastic belt and powder-coated mild steel frame guarantee durability even in demanding conditions.

Ease of Maintenance and Installation

Designed for straightforward floor mounting, the conveyors corrosion-resistant materials and low-maintenance structure minimize downtime. Cleaning is simple, and the lightweight build aids in hassle-free installation, supporting efficient continuous operation.

FAQs of Plastic Belt Conveyor:

Q: How is the belt width of the plastic belt conveyor customized for specific needs?

A: The belt width can be tailored between 300 mm and 800 mm to fit your material handling or packing requirements, ensuring suitable coverage based on the size and volume of items being conveyed.Q: What are the primary benefits of using a modular plastic belt in this conveyor system?

A: A modular plastic belt provides durability, resistance to corrosion, and is easy to clean, making it ideal for environments requiring frequent sanitation or robust material movement.Q: When should the plastic belt conveyor be considered for installation in industrial settings?

A: It is best suited for operations involving material handling, packing lines, and assembly conveyance where reliability, low noise, and ease of maintenance are important.Q: Where can this conveyor be installed most effectively?

A: The floor-mounted design allows installation in factories, warehouses, and production facilities, especially where horizontal movement of goods is essential and vertical or pneumatic conveyors are not required.Q: What process makes maintenance simple for this conveyor system?

A: The corrosion-resistant construction, powder-coated frame, and modular belt design facilitate quick cleaning and reduced need for frequent servicing, keeping ongoing maintenance low and predictable.Q: How does the variable speed feature benefit conveyor operation?

A: Variable speed control, adjustable up to 30 m/min, allows operators to match conveyor pace with production needs, optimizing workflow efficiency and adapting to different types of materials or packaging rates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+