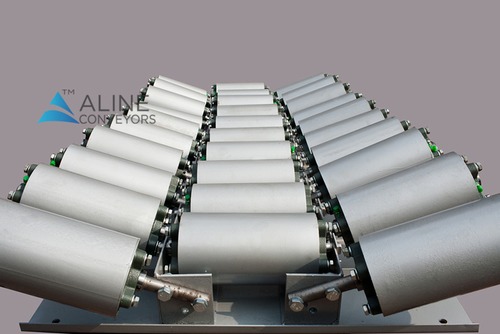

Conveyor Idler Roller

18000 INR/Unit

Product Details:

- Capacity Designed as per application load

- Diameter 50 mm to 219 mm

- Dimensions Customizable as per conveyor design

- Technique Welded/Fabricated using precision machinery

- Standard IS 9295 / CEMA / DIN / JIS

- Belt Width 400 mm to 2400 mm

- Feature Corrosion resistant, Durable, Low noise

- Click to View more

X

Conveyor Idler Roller Price And Quantity

- 18000 INR/Unit

- 40000.00 - 45000.00 INR/Unit

- 1 Unit

Conveyor Idler Roller Product Specifications

- 400 mm to 2400 mm

- Customizable as per conveyor design

- 50 mm to 219 mm

- Designed as per application load

- Welded/Fabricated using precision machinery

- Corrosion resistant, Durable, Low noise

- IS 9295 / CEMA / DIN / JIS

Conveyor Idler Roller Trade Information

- 200 Unit Per Day

- 3-4 Week

- Yes

- All India

Product Description

The efficiency of our Conveyor Idler Roller is prominent in the market. We have been able to come a long way because of the premium quality products. Our innovative professionals design and develop this roller in an exceptionally well manner and enable our company to stand strong in the competitive market. This Conveyor Idler Roller made by us simplifies the business operations of our customers and boots their productivity. We are happy to see that our efforts are being successful and we are attaining optimal client satisfaction in all our deals.

Precision Design and Wide Compatibility

Our conveyor idler rollers are engineered to exacting ISO M7/H7 tolerances, available in face lengths and diameters tailored to specific belt widths (400 mm to 2400 mm). Suitable for flat belt and slat conveyors, their robust structure ensures reliable performance in bulk material handling applications, adapting seamlessly to customer design requirements.

Durability and Superior Surface Finish

Fabricated with high-grade materials like Bright Steel, En8, or stainless steel, these rollers undergo a choice of powder coating, painting, or galvanization to maximize corrosion resistance and service life. Each unit is rigorously inspected for structural integrity and finish, meeting the varied needs of demanding industrial environments.

Flexible Application and Customization

Designed with a modular approach, our rollers offer flexibility in seal type, color, load capacity, and structural chain, catering to the unique specifications of each project. We accommodate customer preferences for dimensions, finishing, and other custom parameters to deliver optimal solutions for mining, cement, power plants, and more.

FAQs of Conveyor Idler Roller:

Q: How do you select the appropriate conveyor idler roller size for my application?

A: The correct roller size is determined by the belt width, load requirements, and conveyor type. Our rollers are available with face lengths and diameters from 50 mm to 219 mm, and can be customized according to your specific conveyor design, load capacity (up to 3000 kg), and operational conditions.Q: What benefits does a powder coated, painted, or galvanized finish provide for conveyor idler rollers?

A: Powder coating, painting, and galvanizing enhance the rollers corrosion resistance, protecting them from harsh environments in material handling facilities. This results in a longer service life, reduced maintenance, and greater durability, even when exposed to moisture, dust, or chemicals.Q: Where can these idler rollers be used effectively?

A: These rollers are ideal for bulk material handling applications across industries such as mining, cement, and power plants. Their robust design and flexible customization options also make them suitable for conveying operations requiring durability and low-noise performance.Q: What is the manufacturing process for the conveyor idler rollers?

A: The rollers are fabricated using welded and precision machinery techniques. High-quality materials are selected, followed by processes like surface finishing (powder coated, painted, or galvanized), assembly with labyrinth or grease-filled double seals, and rigorous inspection to ensure conformity to international standards such as IS 9295, CEMA, DIN, and JIS.Q: When should the seals on the idler rollers be checked or replaced?

A: Regular maintenance checks should be performed as part of your plants schedule, especially in harsh environments. Seals need inspection for wear or leakage to maintain roller efficiency and prevent contamination. Our double-sealed or labyrinth seals are designed for longevity but should be replaced if any deterioration is observed.Q: What are the main benefits of using these idler rollers in conveyor systems?

A: Key advantages include high corrosion resistance, low operational noise, robust load capacity, customizable dimensions, and reliable performance in extreme temperatures. These features translate to decreased downtime, improved material handling efficiency, and extended equipment life in demanding industrial settings.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Our Dealing Area: Ghaziabad, Gurgaon, Meerut, Alwar, Faridabad, Noida, Jaipur, Panipat, Rewari, Bhiwari, Karnal, Moradabad, Bareilly, Rohtak, NCR.

Call Me Free

Call Me Free