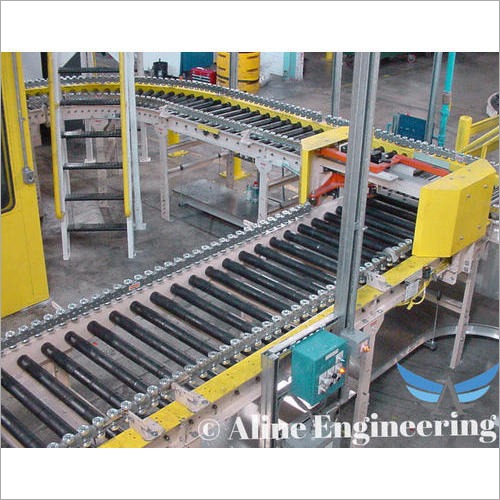

Chain Driven Roller Conveyors

40500 INR/Meter

Product Details:

- Power Source Electric

- Belt Type Not applicable no belt used

- Surface Finish Powder-coated / Galvanized / Painted finish

- Features Customizable length & width, robust drive, reversible operation, low maintenance

- Thickness Frame: 2-5 mm; Roller: 2-4 mm (custom depending on model)

- Material Mild steel, stainless steel or powder-coated steel

- Type Chain Driven Roller Conveyor

- Click to View more

X

Chain Driven Roller Conveyors Price And Quantity

- 40500 INR/Meter

- 1 , , Meter

Chain Driven Roller Conveyors Product Specifications

- Electric

- Not applicable drive is by chain/mechanical power

- Mild steel, stainless steel or powder-coated steel

- Not applicable no belt used

- 0.1 to 1.0 m/s (variable, depends on application)

- Up to 2000 kg/m (customizable)

- Yes, chain-driven

- Powder-coated / Galvanized / Painted finish

- Corrosion-resistant, wear-resistant chain and rollers

- Chain Driven Roller Conveyor

- 0.75 kW 7.5 kW (as per conveyor length and load)

- Customizable length & width, robust drive, reversible operation, low maintenance

- Pallet handling, warehouse automation, heavy industrial conveyance, automotive, packaging

- Modular frame; heavy-duty steel construction

- Not included model is horizontal only

- Not included this is a roller conveyor

- 220V/380V, 3 Phase (customizable)

- Frame: 2-5 mm; Roller: 2-4 mm (custom depending on model)

Chain Driven Roller Conveyors Trade Information

- 1000 , , Meter Per Month

- 3-5 Days

Product Description

Customers throughout the market trust us for making the purchase of Chain Driven Roller Conveyors. We own world-class facilities at our infrastructural unit which helps us in boosting productivity. All our clients are impressed with us and they have become loyal to us. The demand for our Chain Driven Roller Conveyors is increasing on daily basis and to meet them timely, we work round the clock. To get in touch with us buyers can contact via phone call or e-mail.

Product details

|

Material |

Mild Steel |

|

Usage |

Packaging industry |

|

Size |

Various Size |

|

Type |

Chain Driven Roller Conveyor |

|

Capacity |

50-100 Kg/feet |

|

Brand |

Aline |

|

Roller Material |

Steel |

Engineered for Reliability and Adaptability

Constructed with cold or hot-rolled steel, this conveyors modular frame ensures ease of extension up to 20 meters. The customizable design accommodates different roller sizes, pitches, and finish colors, providing flexibility for various material handling requirements. Its corrosion-resistant, wear-resistant rollers and chain drive mechanism guarantee longevity, even in demanding industrial environments.

Advanced Safety and Control Systems

The conveyor system prioritizes operator safety with features such as emergency stop buttons, overload protection, and chain guards. Manual or automated (PLC-integrated) control systems are available to suit your operational needs, providing precise, efficient, and safe transport of heavy goods at variable speeds.

Effortless Integration and Maintenance

On-site assembly and commissioning are available, enabling seamless integration with existing warehouse or production workflows. The rugged, low-maintenance design and reversible operation minimize downtime, while module-based frame extensions allow for future capacity upgrades as your business grows.

FAQs of Chain Driven Roller Conveyors:

Q: How is the Chain Driven Roller Conveyor installed and commissioned?

A: Installation and commissioning are performed on-site by trained professionals. The modular frame design allows for straightforward assembly, and each system undergoes testing upon setup to ensure optimal operation before handover.Q: What applications are ideal for this chain-driven roller conveyor?

A: It is ideally suited for pallet handling, warehouse automation, automotive industry, and heavy industrial conveyance, where reliable transport of large, heavy itemsup to 2,000 kg/mis required without the use of belts.Q: What are the customization options available for roller size, pitch, and color?

A: Roller diameters can be tailored between 50 mm and 89 mm, with roller pitches ranging from 75 mm to 150 mm. The frame can be finished with custom RAL colors to match facility requirements or branding preferences.Q: How does the control system work, and can it be automated?

A: The conveyor system can be operated manually or fully automated through PLC integration, offering seamless integration with existing warehouse management systems to enhance efficiency and monitoring.Q: What safety measures are included with the conveyor?

A: Key safety features include emergency stop switches, overload protection, and chain guards, all designed to safeguard operators during use and protect conveyor components from damage.Q: Where can this conveyor be used with respect to environmental conditions?

A: The system is engineered to operate reliably in temperatures ranging from -10C to +60C, making it suitable for a wide variety of industrial and warehouse settings.Q: What are the main benefits of choosing this chain-driven design over alternative conveyors?

A: Compared to belt or pneumatic conveyors, this chain-driven roller conveyor is highly robust, supports very heavy loads, requires less maintenance, and offers greater flexibility in configuration and automation.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Conveyor System' category

Our Dealing Area: Ghaziabad, Gurgaon, Meerut, Alwar, Faridabad, Noida, Jaipur, Panipat, Rewari, Bhiwari, Karnal, Moradabad, Bareilly, Rohtak, NCR.