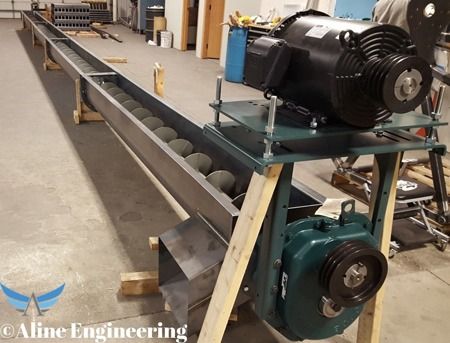

I Beam Model Conveyor

6500 INR/Meter

Product Details:

- Belt Type No belt trolley-based

- Thickness 6 mm to 12 mm (I Beam)

- Features Heavy duty, easily customizable layout, low maintenance, high load bearing

- Power Source Electric

- Surface Finish Powder coated or painted

- Material Mild Steel (MS)

- Type Overhead I Beam Conveyor

- Click to View more

X

I Beam Model Conveyor Price And Quantity

- 10 Meter

- 6500 INR/Meter

I Beam Model Conveyor Product Specifications

- No belt trolley-based

- Not included

- Mild Steel (MS)

- I Beam section, robust steel construction

- Optional as per requirement

- Corrosion and wear resistant

- 6 mm to 12 mm (I Beam)

- Up to 2000 kg per trolley

- 415 V (Three Phase)

- Heavy duty, easily customizable layout, low maintenance, high load bearing

- 2 HP to 5 HP

- Not included

- Not included

- Powder coated or painted

- Electric

- Overhead I Beam Conveyor

- Automobile, paint shops, assembly line, warehousing, material handling

- 3 to 10 m/min

I Beam Model Conveyor Trade Information

- 1000 Meter Per Month

- 3-5 Days

Product Description

This product is designed to run on I beam track with tapered flanges, which is why they are known as I Beam Model Conveyor and have generally the prefix. We have hired expert professionals in our company who work round the clock and implement innovative ideas, thereby, helping in the growth of the company. To know more about our I Beam Model Conveyor you can contact us freely, our team will explain everything in detail and will clear all your doubts.

Product details

| Capacity | 50-100 Kg/feet |

| Automation Grade | Automatic |

| Voltage (Volt) | 220 V |

| Material | Mild Steel |

| Brand | Alive |

Versatile Customization for Any Application

The I Beam Model Conveyor is designed for flexible integration into various industrial setups. Clients can select trolley pitch, mounting type, and finish color to match specific process requirements or spatial constraints. Robust construction ensures reliable performance for large-scale automated and manual operations.

Durable Structure and High Load Capacity

Engineered from mild steel and powder-coated or painted, the conveyor offers exceptional corrosion and wear resistance. Its forged alloy steel chain and substantial I Beam section deliver consistent support for loads up to 2000 kg per trolley, suitable for heavy-duty applications and frequent use.

Efficient, Low-Maintenance Operation

With grease-lubricated bearings and a low operating noise profile, the conveyor minimizes downtime while reducing environmental disruption. Its manual or motorized drive provides effective adaptability for different usage scenarios, and installation support ensures seamless setup on-site.

FAQs of I Beam Model Conveyor:

Q: How is the I Beam Model Conveyor installed and what support is provided?

A: The conveyor can be installed as ceiling suspended or floor mounted, depending on site requirements. Our team offers comprehensive on-site installation support to ensure precise setup, optimal alignment, and operational readiness for your specific application.Q: What is the maximum load capacity per trolley and what type of chain is used?

A: Each trolley on the I Beam Model Conveyor supports up to 2000 kg, enabling transport of heavy goods and components. The system utilizes an alloy steel forged chain for excellent strength and durability, ensuring long-term reliable performance.Q: When should I choose the motorized versus manual drive operation method?

A: Motorized drive is recommended for applications requiring efficient, automated material movement at speeds between 3 to 10 m/min, especially in high-volume environments. Manual drive is suitable for less frequent operations, or where precise manual handling is needed.Q: Where can the I Beam Model Conveyor be used, and what industries benefit most?

A: This conveyor model is ideal for automobile manufacturing, paint shops, assembly lines, warehousing, and general material handling scenarios. Industries demanding high load-bearing capacity, durability, and customizable layouts benefit the most from its deployment.Q: What maintenance practices promote long service life for the conveyor?

A: Routine greasing of the bearings, regular inspection for wear or corrosion, and maintaining the powder-coated or painted surface all contribute to extending the systems operational lifespan. The conveyors design emphasizes low maintenance requirements for ease of ownership.Q: What are the benefits of its powder-coated or painted finish?

A: Powder coating or painting enhances the conveyors resistance to corrosion and wear, improving its ability to withstand harsh industrial environments and exposure to chemicals, dust, and moisture. Clients may choose standard black or request a custom color.Q: Is a vertical or pneumatic conveyor option available?

A: A vertical conveyor system is optional and can be included upon request to accommodate specific process needs. However, pneumatic conveyor features are not part of this models configuration.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Industrial Conveyor System' category

Our Dealing Area: Ghaziabad, Gurgaon, Meerut, Alwar, Faridabad, Noida, Jaipur, Panipat, Rewari, Bhiwari, Karnal, Moradabad, Bareilly, Rohtak, NCR.

Call Me Free

Call Me Free